Why should I buy a Blast Chiller/Shock Freezer?

- Prevent bacterial growth

- Retain the integrity of product

- Avoid wastage

- Extend shelf life

- Meet HACCP guidelines

Why Irinox?

Irinox is the only company entirely devoted to the design and manufacture of blast chillers. Irinox is a specialist Company that has pioneered the development of innovative equipment using the highest quality mechanical components available. As a result, Irinox blast chillers can work consistently 24/7 for up to 15 years with very little maintenance, to perform the task of keeping food items perfectly fresh. This makes Irinox unique in the field of blast chilling and shock freezing.

The integrity of the machinery, ‘intelligently’ driven by complex on-board electronic programs allows for a high degree of control over important factors like: speed and direction of air flow, humidity, cooling temperature (which is monitored to ensure rapid, but gentle cooling without unintentionally freezing) and the heat load on the compressor itself.

The freshest possible way to cook…

When food – any food – that has been treated with this amount of care is later regenerated for serving to discerning customers, it presents with none of the stressed-out effects normally associated with “pre-cooking and storing.” Consider the Irinox way the freshest possible way to cook; plus a highly cost effective and efficient means of providing quality on the plate.

THE BLAST CHILLING – SHOCK FREEZING ‘EFFECT’ ON FOODS

An Irinox blast chiller is also a shock freezer, these machines offer the most advanced technology in their field. Irinox blast chillers/shock freezers operate in an efficiently and timely manner. The ability to perform the ‘task’ (chilling or freezing) quicker means great savings can be made:

- More food can be processed each day

- Freshness lasts longer

- Shelf life is extended

- Fragrance and colour are preserved

- More time is available

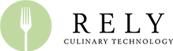

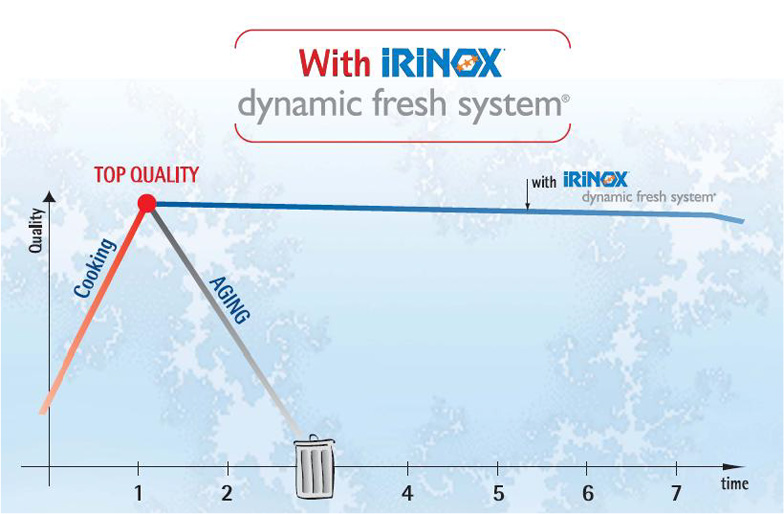

Let’s look at how food ages and why, then how Irinox, slows that deterioration

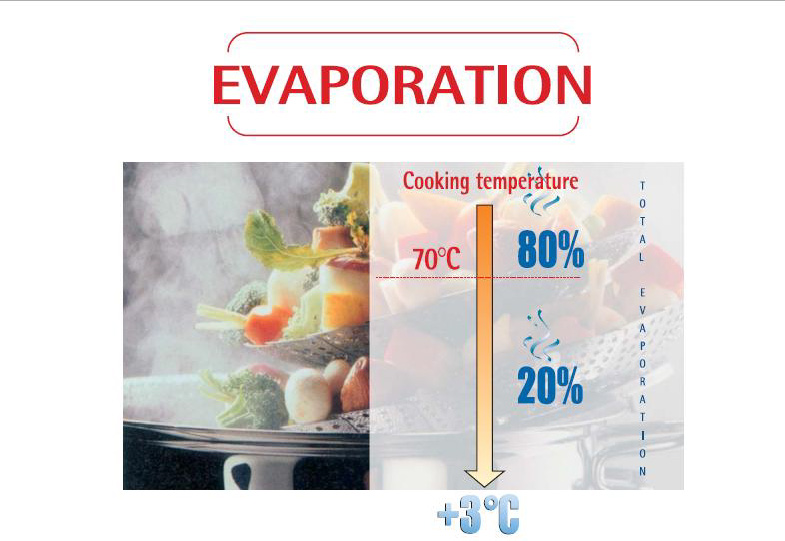

The visual explanation shows that food spoils quickly under normal conditions

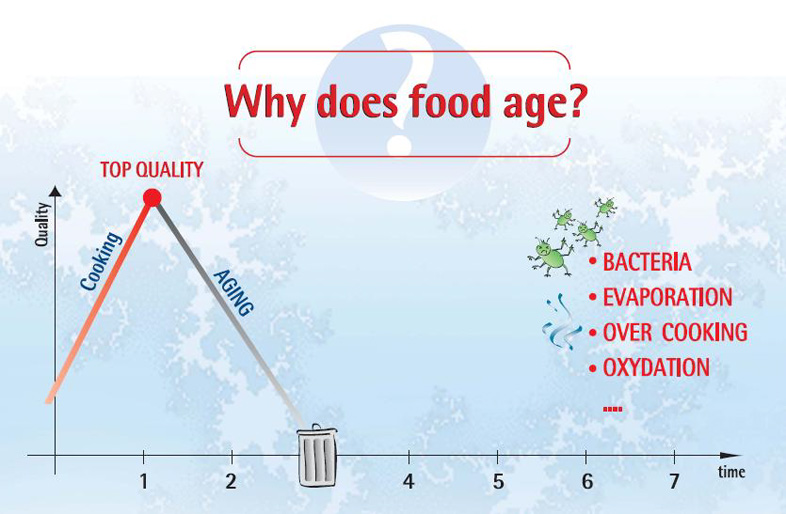

This spoiling happens because food takes time to cool under normal conditions

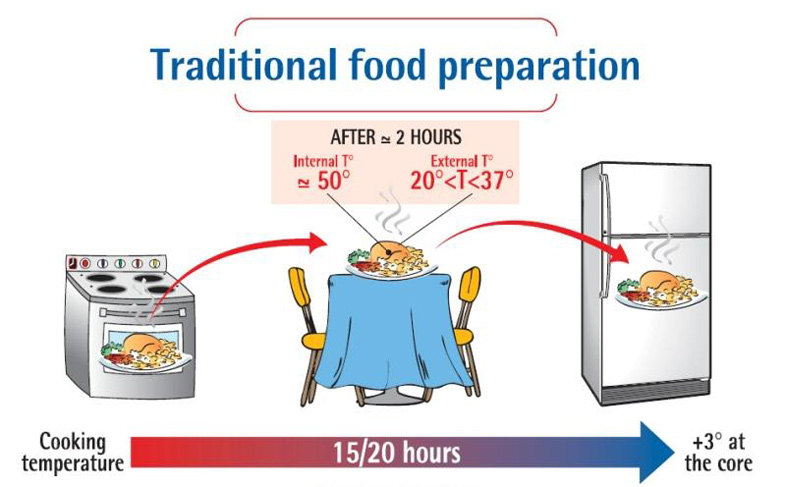

Bacteria grows at a fast rate in temperatures above 5°C

And evaporation of moisture happens too quickly BUT

With correct air ventilation and refrigeration food can be cooled or frozen quicker – thus

- locking in flavor

- stopping loss of weight through evaporation

- preserving the product perfectly.

BACKGROUND INFORMATION

Thirty years ago, it was felt by a few that there was a requirement in the industry for certain foods to be cooled quicker than current refrigeration allowed. Irinox was one of the first companies to develop the modern blast chiller / shock freezer 25 years ago. When the company was formed, research, development and special attention to customer needs was the focus. These machines were to be sold as a complete unit, manufactured totally of food grade stainless steel.

In the early nineties, Irinox developed a worldwide market in most areas within the food industry and was seen as a force within these disciplines. Research and development allowed Irinox to invent, launch and copyright, hard chilling and continue to perfect soft chilling.

Freezing has been, the last line of defence in product management. However, important features of the Irinox shock freezing cycle are:

- Speed of process

- Retention of greater amounts of moisture

- Ability to freeze any product

- Low energy usage in this rapid and intense cycle

- The ability to continuously use this cycle without defrosting the evaporator

- No deterioration of product on defrosting

It is important to understand the effect that Irinox had on the market at this time and to see the difference in the type of machinery that Irinox offers in the market today.

It is paramount in chilling never to peripherally freeze any product as this defies the use of a ‘blast chiller.’ (Contemporary refrigeration had this effect on food at low temperatures). The ability to provide a system that chills food using only positive air at lower core temperatures, (in other words from 100 – 30), and continuing the process of chilling within the time frames required, would normally be impossible. There is always a delta, or difference, between core and air temperatures and if this delta is minimal the time taken to chill to 30 would normally be quite lengthy. However, the Irinox system utilises indirect air flow, specially designed ventilators, individually weighted ergonomic fans and a cabinet which has been designed, taking into account the size of the various components, to perfectly chill the product using these positive air temperatures in the lower temperature part of the process. This is a key ingredient in the perfected blast chilling system, by IRINOX.

The value of Irinox is the provision of a machine that allows the consumer to comply to the new HACCP regulation, and return control to the end user, by allowing better management in food cost, quality and staffing.

A range of benefits which are noticeable include:

- Larger menus can be offered without incurring substantial costs

- Redeploying of staff in the kitchen where once repetitive work had to be done daily

- The labour cost is better controlled as kitchen staff are now able to work within normal hours and yet be more productive and creative

- Greater amounts of moisture are kept within the product, thereby giving longer shelf life and total integrity to the food in its colour, flavour and aroma, by placing the product immediately from the cooking environment in the cabinet (+900 core temperature)

Blast chilling and shock freezing is a relatively new industry and one which business owners need assistance in both understanding the use of, and the application of, its various capabilities. Irinox has always known that it is important to give every industry the ability to continue their work, without this new technology confusing them.

Advice and Consultancy on Blast Chilling / Shock Freezing – please contact

Robert Erskine – robert@relyservices.com.au – 0409 354 669